Case Study

Background

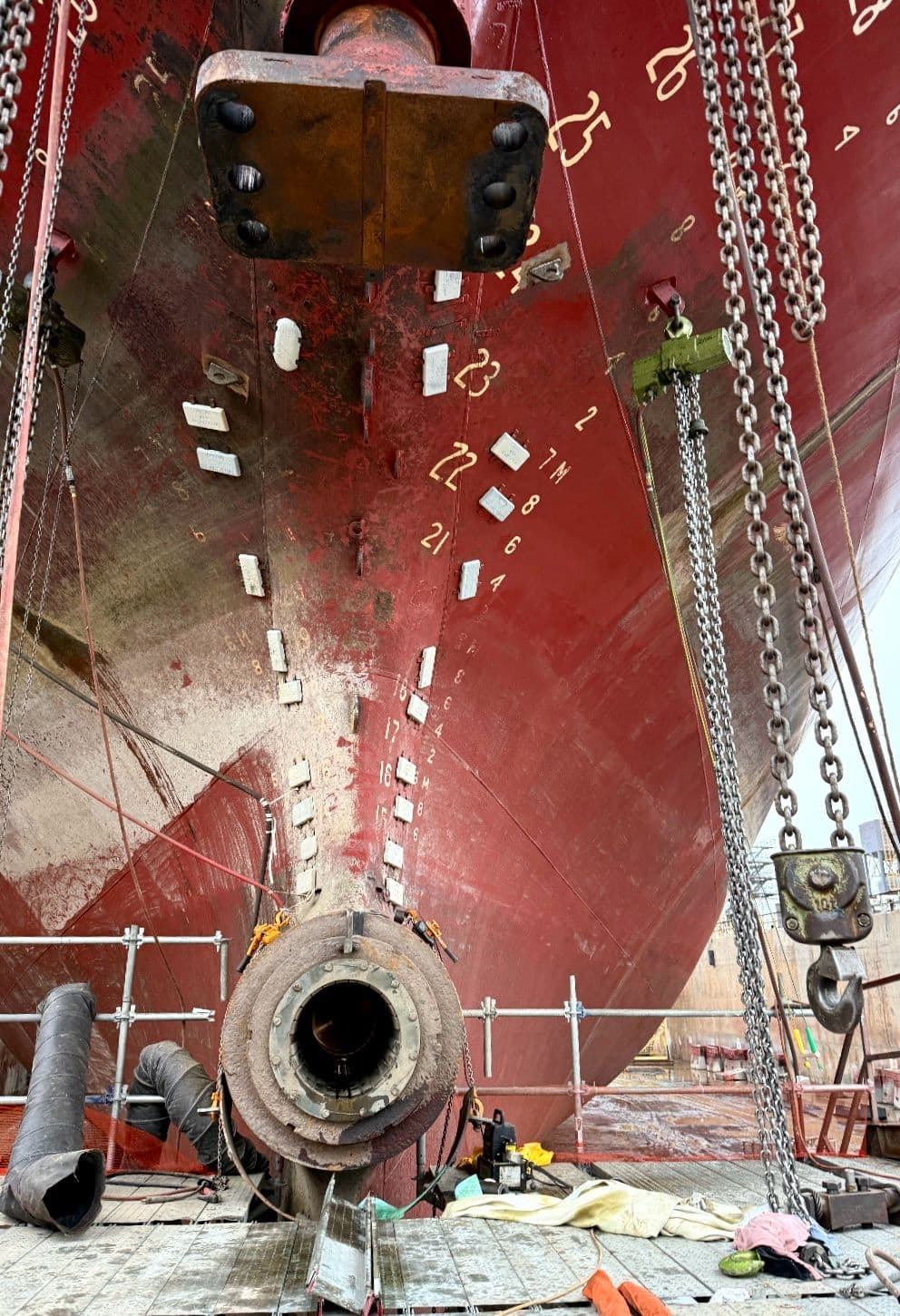

- The CSL Frontenac, built in 1968 by Davie Shipbuilding Company, has a long history of durability and efficiency.

- Powered by a single shaft with a 23-inch diameter.

- Underwent multiple maintenance cycles, including bearing replacements.

- Lignum Vitae (LV) bearings have been critical for operation in harsh marine environments.

- After 50 years and two sets of LV bearings, CSL contacted Lignum Vitae North America (LVNA) for another replacement.

Challenges

- Source high-quality, durable bearings for long-term support of the vessel.

- Maintain CSL’s trust by delivering bearings that meet the ship’s specific needs.

Solution

- LVNA designed custom pre-assembled end-grain staves for the bearings.

- Produced the staves in LVNA’s Virginia shop and shipped them to the shipyard.

- Utilized Lignum Vitae’s durable and self-lubricating wood for optimal performance.

Installation Process

- Day 1: Efficient removal of old bearings.

- Day 2: Seamless installation of new end-grain staves.

Results

- Successful installation secured the ship’s continued smooth operation.

- Lignum Vitae wood offers resistance to wear, corrosion, and extreme conditions.

- Minimal downtime and reduced maintenance costs for CSL Frontenac.

- Enhanced dependability and efficiency for CSL and its customers.

Conclusion

LVNA’s expertise delivers high-performance bearings with exceptional longevity.

The CSL Frontenac benefits from bearings that ensure years of reliable service.

Partner with Lignum Vitae Solutions

Discover how our expertise and the unmatched performance of Lignum Vitae can benefit your operations. Contact us today to discuss your specific needs.